Highlights

Meet a CQTian: Joven Kwek

Joven enjoys being in nature and ‘forest bathing’ in Singapore’s primary rainforests. Image credit: Joven Kwek

Joven enjoys being in nature and ‘forest bathing’ in Singapore’s primary rainforests. Image credit: Joven Kwek

Who are you?

My name is Joven. I am a research support staff. My colleagues and I form a close-knit group with different professional skill sets supporting CQT’s research experimentalists.

How did you end up in a quantum research centre?

Before I joined CQT, I was working as an Associate Engineer in the Satellite Remote Sensing industry. I viewed earth photographs taken from space, which was still unheard of by the general public as Google Maps was still unavailable then. In 2008, during an impromptu walk, CQT’s newly furnished corridor and labs caught my eye. Images of its labyrinth of optical tables and new mechanical and electronics workshops resonated in my mind. It looked like a cool place to work and an environment which encouraged creativity. I applied and now, I’ve been here for more than a decade.

What is your role at CQT?

I started off supporting our research groups in electronics prototyping, PCB boards prototype fabrication and occasionally light CNC (Computerised Numeric Control) work. As technology evolves, new techniques and materials have been explored and used in quantum experiments. My current work takes me to the field of laser micro-machining. I also provide support in cleanroom environment processes. Most of this work happens in the Engineering Faculty where I have a satellite office. I see myself as a CQT ambassador where I share and tap engineering resources between different faculties to bring CQT’s research work to a new level.

Tell us more about your expertise with laser micro-machining and working in a cleanroom.

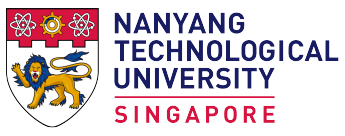

This is a topic that I can spend whole day talking about. In laser micro-machining, I specialise in the fabrication of micro-sized structures. One of the applications include ion trapping in quantum computing experiments. Laser micro-machining involves operating a highly specialised laser system to ablate material. Just imagine drilling tiny holes on a human hair!

Joven’s work involves fabricating micro-structures. In the pictures, he ablated a titanium tube 1mm in diameter with CQT’s logo. See the size of the tube in comparison with the size of Singapore’s ten-cent coin in the top right corner. Image credit: Joven Kwek

Joven’s work involves fabricating micro-structures. In the pictures, he ablated a titanium tube 1mm in diameter with CQT’s logo. See the size of the tube in comparison with the size of Singapore’s ten-cent coin in the top right corner. Image credit: Joven Kwek

Working in a cleanroom environment could involve operating deposition and growth equipment like ultra-high vacuum e-beam evaporators, using advanced metrology and test techniques such as a scanning electron microscope or surface profiler station such as the DektaK XT to characterise surface quality in micro precision. I also do procedures such as wire bonding and wafer dicing, just to name a few.

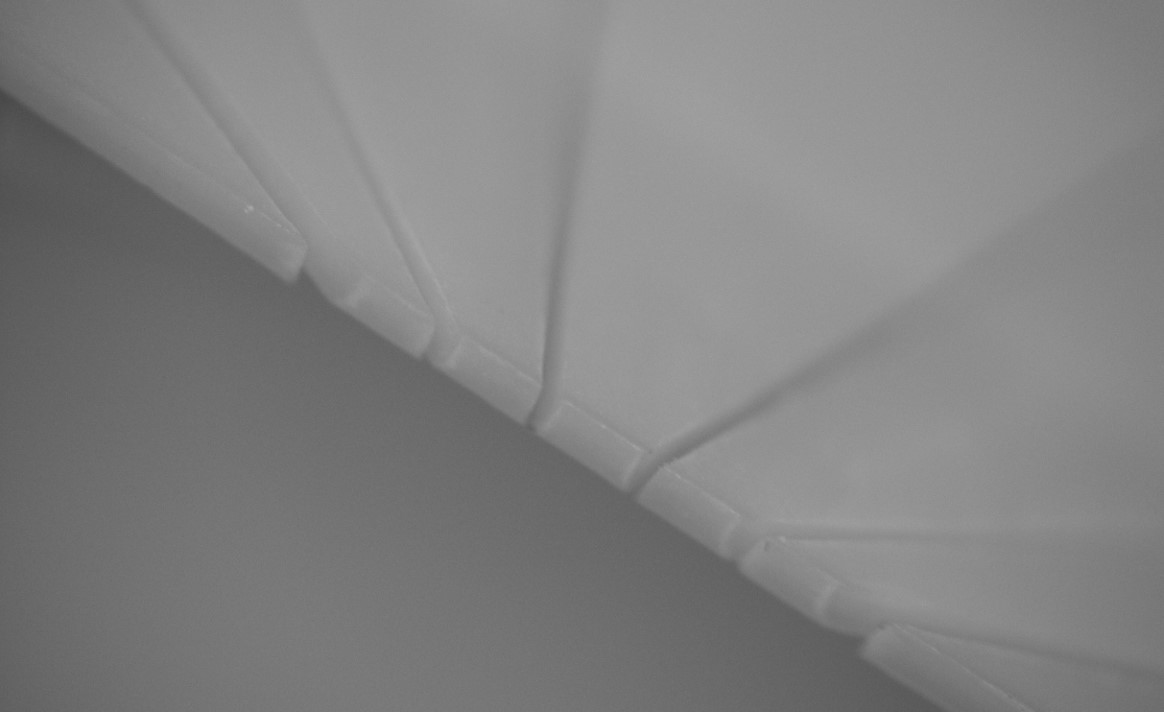

What is the hardest part about your work?

Keeping my “customers” happy and not compromising the quality of my work. It can be very challenging as my work often needs to be inspected under extreme magnification. Flaws and imperfections cannot escape people’s eyes. On the flip side, it encourages me to be careful and detailed in my fabrication work, which I am very proud of. I believe once we become good at what we do, things will usually flow and turn out well.

What is your favourite aspect of your work?

The unique nature of the job where I am constantly faced with new challenges in micro-fabrication techniques. I am only scratching the surface of this new technology and I have a lot to learn. The encouragement and support from our PIs and CQT management allows me to explore and improve.

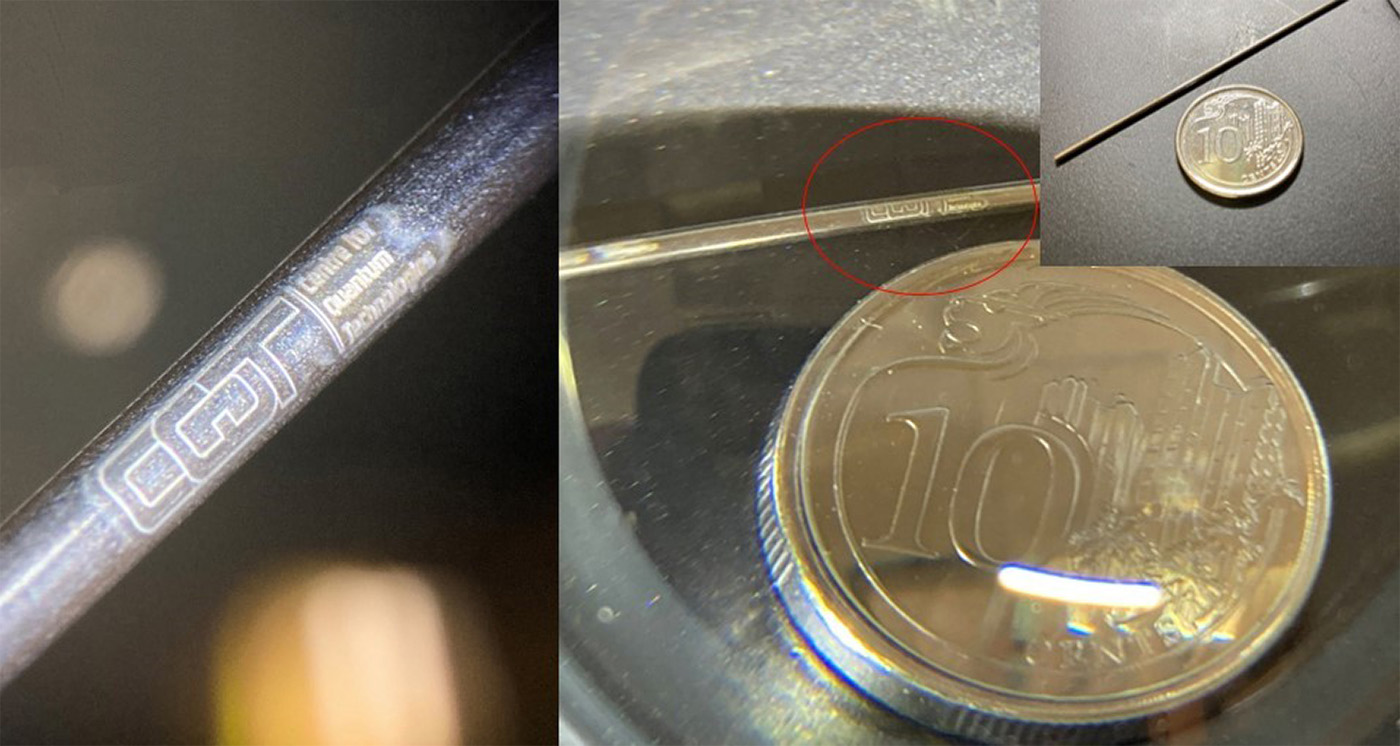

Pictured is a precision laser etched alumina ceramic micro structure for ion trapping. Fabricating these specialised devices is part of the work being done under the quantum foundry supported by Singapore’s Quantum Engineering Programme. Image credit: Joven Kwek

Pictured is a precision laser etched alumina ceramic micro structure for ion trapping. Fabricating these specialised devices is part of the work being done under the quantum foundry supported by Singapore’s Quantum Engineering Programme. Image credit: Joven Kwek

What is a typical day like for you?

The Roman Poet Horace said “Seize the day”. I like to start my day early in campus with a clear mind preparing fabrication algorithms and approaches. Else, I would be shuttling between tasks in dry labs or cleanrooms. The later part of the day would usually consist of project discussions with respective research groups members, and I end the day with typical office errands.

Is there a project that you were most proud of?

I was asked if I could do a presentation by our collaborator in the Engineering Faculty during their open house in 2020. There, I had the opportunity to share my work and to represent CQT. It was attended by researchers of different background and industrial partners. The presentation was well received.

What are your hobbies outside of work?

I enjoy nature and everything that has to do with flora and fauna. Nature is the place where I feel most at ease. Mother Nature is so rejuvenating for one’s body and soul. One activity I enjoy is ‘shinrin-yoku’, in Japanese, or ‘forest bathing’. It is simply being in nature, connecting with it through our sense of sight, hearing, smell, taste and touch. I do that regularly in our local primary rainforests such as the Central Catchment area or Bukit Timah Nature Reserve. It very therapeutic and I encourage everyone to try it.

Would you like to share anything about yourself that other people might be surprised to know?

Well, it might be a bit old school, but I still occasionally scribble a few words with fountain pen as a form of calligraphy. I also try to live mindfully – as the Dalai Lama said, “There are only two days in the year that nothing can be done. One is called yesterday and the other is called tomorrow. Today is the right day to love, believe, do and mostly live.”

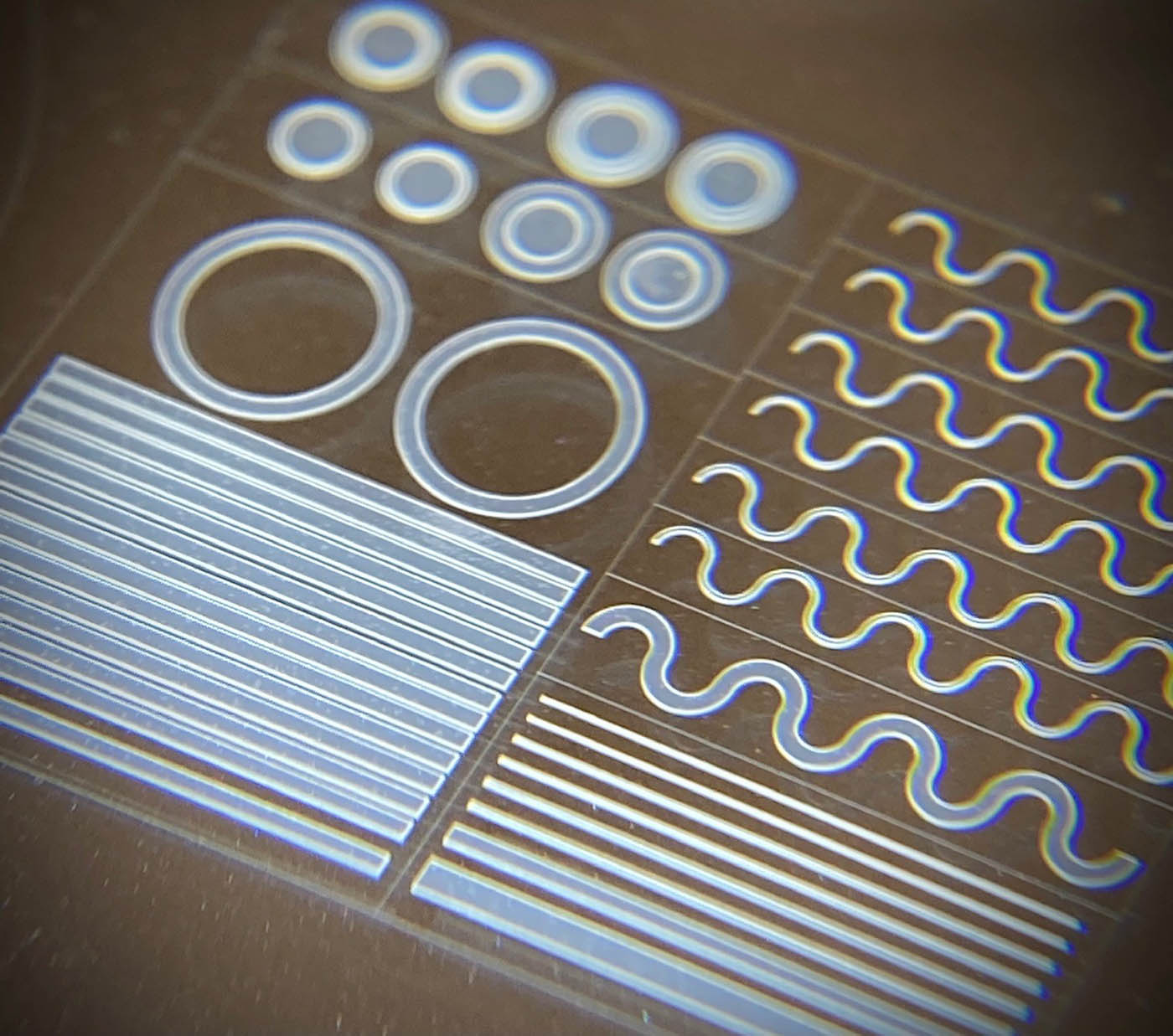

These precision laser etched micro structures on a heat sensitive polymer material are only about 50-100 micrometres in length. Under extreme magnification, flaws and imperfections cannot escape people’s eyes. This encourages Joven to be careful and detailed in his fabrication work. Image credit: Joven Kwek

These precision laser etched micro structures on a heat sensitive polymer material are only about 50-100 micrometres in length. Under extreme magnification, flaws and imperfections cannot escape people’s eyes. This encourages Joven to be careful and detailed in his fabrication work. Image credit: Joven Kwek

Learn more

Related Stories

| Meet a CQTian: Mohammad Imran June 28 2021 |

| Meet a CQTian: Angelina Frank May 24 2021 |

| Meet a CQTian: Alessandro Luongo June 09 2021 |