Highlights

Stretchy polymer makes good waveguides

Optical devices built from the polymer polydimethyl siloxane can be tuned by stretching, CQT researchers report in Applied Physics Letters

Optical devices built from the polymer polydimethyl siloxane can be tuned by stretching, CQT researchers report in Applied Physics Letters

Researchers at the Centre for Quantum Technologies have started building optical devices from an unexpected material: a polymer like that used to seal the edges of sinks.

A big advantage is being able to tune the devices’ behaviour by simply stretching or bending the flexible material. “This research started out sounding like crazy talk and yet it worked,” says Alexander Ling, the groups’ Principal Investigator.

It offers a new approach to building the kinds of integrated optical systems that are widely used in industry and research, for example for feeding data-carrying light beams into optical fibres or for miniaturising lab experiments.

The team describe their findings in a paper published 22 November in Applied Physics Letters. The project was carried out with collaborators at the Centre for Advanced 2D Materials (CA2DM) and Graphene Research Centre, also at the National University of Singapore.

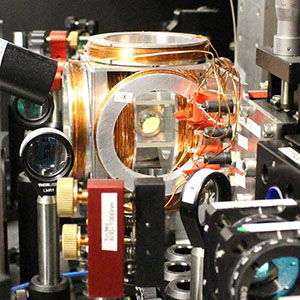

“We didn't jump straight into wacky elastomer systems,” said Research Fellow James Grieve. He had started out by using lasers to write optical paths into glass. That’s an established technique, which he applied to a new kind of glass. It worked but did not have as many advantages as hoped for – prompting a search for something new.

James knew that the polymer polydimethyl siloxane (PDMS) was already used by scientists who do biology and chemistry experiments in miniature ‘lab on a chip’ setups. These microfluidic chips sometimes have inputs for light. Ng Kian Fong, then an NUS undergraduate doing his final-year project and now a Master’s student, joined the team to start experiments on this material.

Teaming up with Manuel Rodrigues and José Viana-Gomes at CA2DM, James and Kian Fong first tried making in PDMS a long, thin path to guide light - a simple waveguide. “It worked first time,” recalls James.

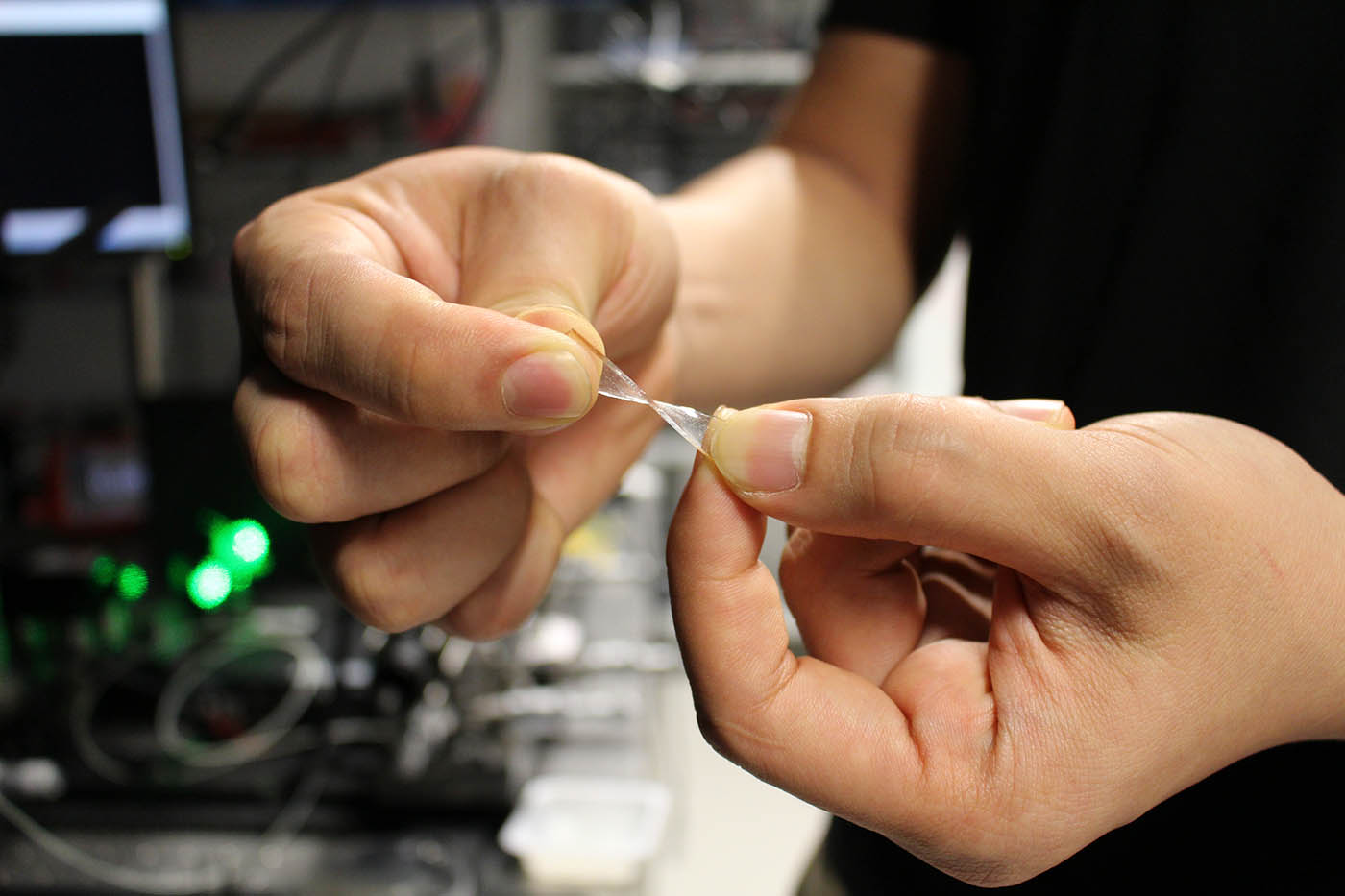

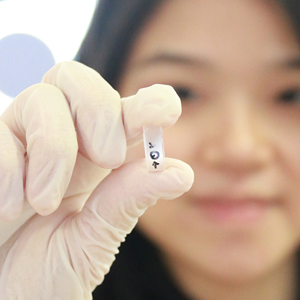

To build the device, the team used a simple moulding technique. Manuel and Jose create a mask with the pattern of the waveguides. James and Kian Fong then coat it with a thin layer of liquid PDMS. That’s baked at high temperature. Afterwards, they pour a thicker layer of PDMS over the top and cure this at low temperature. The whole structure, measuring around 2cm on each side and up to a millimetre thick, can then be peeled away.

In the paper, the team report these waveguides work for a wide range of optical frequencies of light, and that they function the same regardless of the light’s polarisation (that’s not always true in other materials).

Moving beyond a simple waveguide, the team built a beamsplitter. This has two parallel waveguides. Send light down one waveguide and some of the light will split off, or couple, into the second waveguide.

The remarkable feature of the PDMS beamsplitter is that the team could control how much light splits off by stretching the device. If they stretched the sheet a few millimetres to pull the two waveguides further apart, they reduced the coupling and thus the light transfer. Release it and the device pops back to its original shape – even after hundreds of stretches.

Integrated optical systems have always had the advantage of being smaller, more stable and more scalable than devices built from many components, but with the limitation of having less control to tune properties after they are built. The PDMS system may bring the best of both worlds.

Next the team will explore more sophisticated ways to stretch their PDMS structures. Instead of pulling at the edges of the whole sheet, they might try poking different parts of a larger waveguide pattern from underneath. In addition to building bigger, more complicated devices the team will also try adding other materials into the PDMS to give it new optical properties.

“We have this platform we believe is suitable for the kind of photons we like to play with in quantum optics, so we invite people who’d like to propose experiments to collaborate with us,” says James.

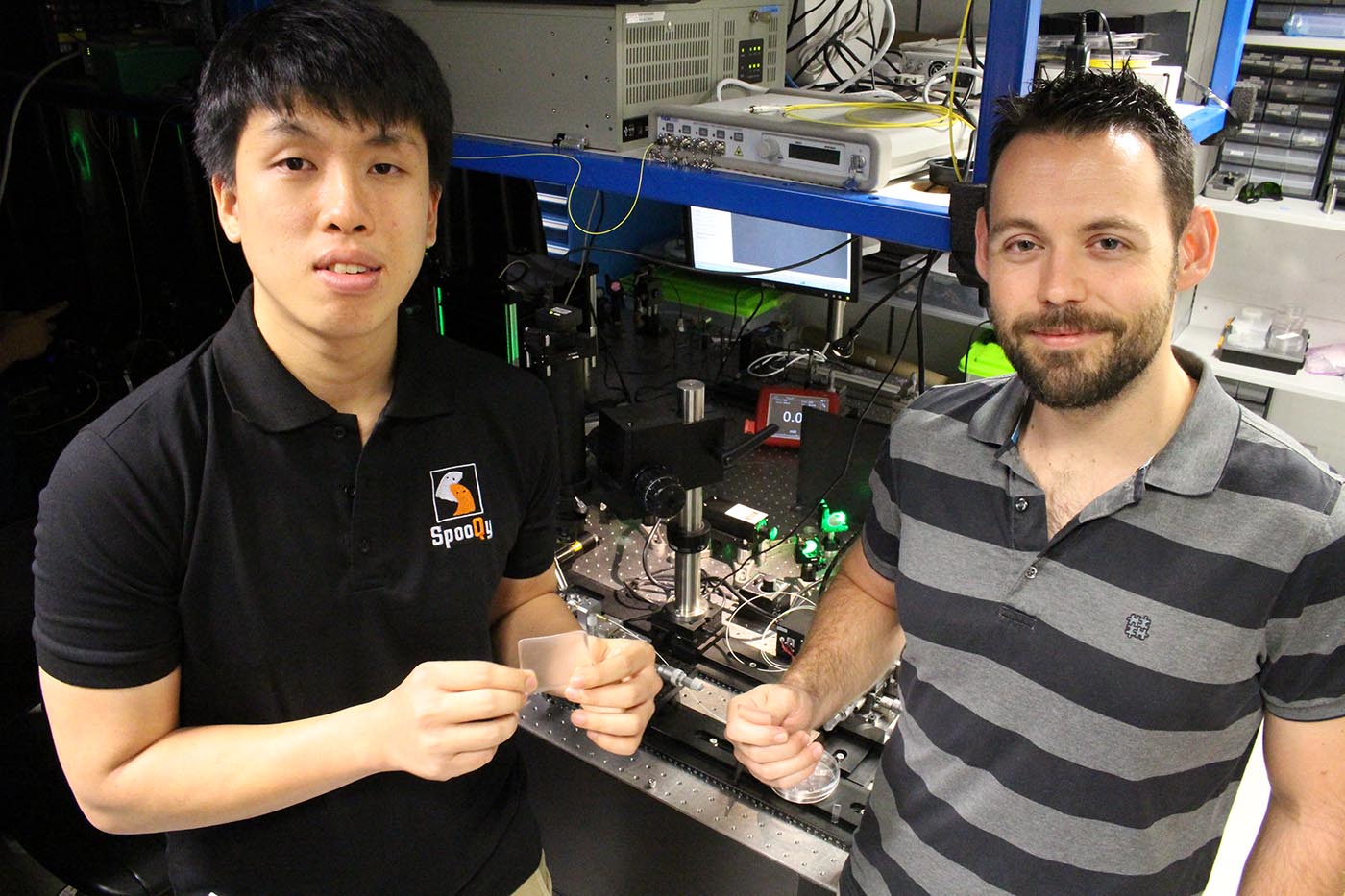

CQT's Kian Fong (left) and James (right) led work on this project.

CQT's Kian Fong (left) and James (right) led work on this project.

Learn more

Related Stories

| Twisted photons enable precision measurement October 03 2013 |

| Thick crystals shine in photon-pair source tests March 21 2016 |

| Lens trick doubles odds for quantum interaction October 31 2017 |